Sold By

NCIEM

(0 customer reviews)

Top Selling Products

-

Testo 270 Cooking Oil Tester

SAR2,000.00 -

Hioki DT4222: Digital Multimeter

SAR390.00 -

HTA102 Sound level Meter with Calibrator

SAR4,000.00 -

Megger MIT1525 - 15kV Insulation Resistance Tester

SAR30,000.00 -

Flir E8-XT InfraRed Camera with MSX & WiFi

SAR15,000.00

| Description: The Metravi CTG-01 Coating Thickness Gauge works both on the magnetic induction principle and on the eddy current principle, depending on the type of probe used. You can select the type of probe via MENU system, or it will work automatically. The gauges confirm to the following industrial standards: GB/T 4956 -1985, GB/T 4957 – 1985, JB/T 8393 – 1996, JJG 889-95, JJG 818-93.

This compact and handy gauge is designed for non-destructive, fast and precise coating thickness measurement. The principal applications lie in the field of corrosion protection. It is ideal for manufacturers and their customers, for offices and specialist advisers, for paint shops and electroplaters, for the chemical, automobile, ship-building and aircraft industries and for light and heavy engineering. The CTG-01 gauge is also suitable for laboratory, workshop and outdoor use. The probe can work on both principles, magnetic induction and on the eddy current principle. The same probe works for coating measurement both on ferrous and non-ferrous metal substrates. It is adaptable to specific tasks: ie. it can be used on special geometries or on materials with special properties. Description of the Gauge For measurement on steel substrates, the gauge works on the Magnetic Induction principle, and for measurement on non-ferrous metal substrates, it works on the Eddy Current principle. Measurement values and user information are displayed on the LCD, The backlight ensures easy reading of screen data even in dark conditions. Two different operating modes are available: DIRECT mode is recommended for simple, quick, occasional measurements. It provides statistical analysis. Single values are not saved. The statistical analysis program can evaluate upto 80 readings. GROUP mode permits measurement and storage of readings in a free programmable memory. A maximum of 400 readings and 4 series of measurements can be analysed according to various statistical criteria. Standard Accessories Gauge with two 1.5V Batteries, Hard Carrying Case, Operating Manual, Steel and Aluminium substrates for calibration, USB Connecting Cable, Software CD for Windows Probe The Probe system is spring-mounted within the probe sleeve which ensures safe and stable positioning of the probe and constant contact pressure. A v-groove in the sleeve of the probes facilitates reliable readings for small cylindrical parts. The hemispherical tip of the probe is made of hard and durable material. |

There have been no reviews for this product yet.

Related products

SAR10,000.00

PFlow P117 Handheld Ultrasonic Flow Meter

SAR1,000.00

BH-4A Portable Multi Gas Detector LEL O2 CO H2S

SAR10,000.00

Sonel PAT-10 Portable Appliance PAT Tester

SAR4,500.00

AT528L Handheld Battery meter

SAR1,450.00

NEW WS-1051 Wireless Weather Station

SAR250.00

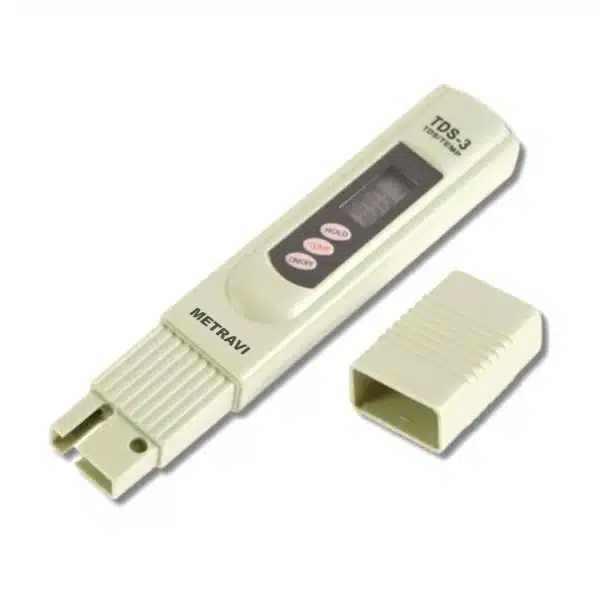

TDS-3 Digital TDS Meter

SAR105.00

PH-700 Digital pH Meter

SAR55.00